Modules & Features

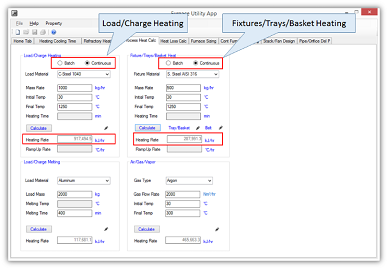

Heat Load Calculations for Process Heating of Metals, Liquids, and Gases

- Heat required to raise solid from an initial to a final temperature

- Heat required to raise liquid from an initial to a final temperature

- Heat required to raise gases from an initial to a final temperature

- Heat required to melt solid metals

Heat Load Calculations for trays/baskets/belts/piers

- Heat calculations to raise support or containers from an initial to a final temperature

- Supports could be piers and containers could be trays or baskets

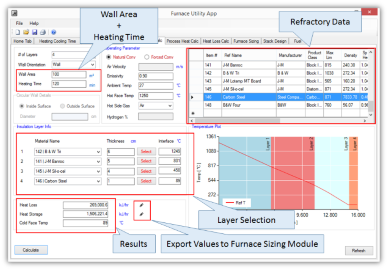

Heat Loss Calculations through Refractory Layers

- Calculation of Heat Loss through multiple layers of refractories

- Calculation of Heat Storage in multiple layers of refractories primarily for Batch Applications

- There is a provision for integrating results for multiple surfaces

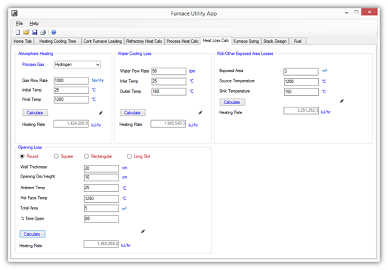

Heat Loss Calculations for Openings, Atmosphere, Water, Slots

- Heat Loss Calculations through Furnace openings like Doors or survey ports

- Heat requirement for heating atmospheric gases

- Heat requirement for skid water heating

- Heat Loss through Slots

- Roll Loss

Heating and Cooling Time of charges in various processes

- Calculation of total Heating and Cooling Time

- Determination of part temeparture profile

Furnace Sizing for both Continuous and Batch Type Furnaces

- All the Heat Losses, Heat Storage, Heat to Metal can be transferred with a click of a button

- Select Furnace Temperature

- Select Heating Mode. The options are Electric, Gas, or Oil Fired

- For Electrical heating select Phase Type, Voltage and Efficiency

- For Combustion select Fuel Type, Combustion Air Temp, Excess Air % and Fuel Temp

Combustion Analysis / Electric Power Calculations

- Calculates Total Heat Demand and Gross Heat Input

- Calculates Fuel and Air Rate

- Flues Data, For Example, Heat Rate, Mass/Volume Rate and Flue Tempearture

- Calculate Electric Power and Total Current for Electrical Heating

Electrical Elements Design

- Calculates Number, Length and Diameter/Width of Electrical Elements

- Calculates Element Temperature from Element Resistivity, Voltage and Current

- Comes with various elements having different resistivity

Stack Design Calculations

- Calculates Theoratical Draft, Stack Frictional Loss and Stack Diamater

- Inputs are Flue Rate, Flue Tempearture, Furnace Pressure and Stack Height

Fan Design Calculations

- Calculates Theoratical and Actual Power

- Inputs Gas Flow Rate, Gas Temperature, and Fan/Blower Pressure

Pressure Drop in Pipe Networks and Across Orifices Plates

- Calculates Pressure Drop in Pipe System

- Inputs are Pipe Dimensions, Valves & Fittings Types, and Gas or Liquid flow info

- Calculates Pressure Drop across Orifice Plates

Loading characteristics and Furnace Length of Continuous Furnace

- Calculates Total Furnace Length from Production Rate, Furnace Width and Residency Time

- Calculates Transport Speed

- Calculates Tray/Basket or Belt Mass Rate rate for a given Transport Speed